At AGM Services, we are dedicated to meeting the highest possible standards for our customers. This goes for scheduled maintenance, breakdown or testing; and it’s no different with the materials we supply, especially when it comes to spray booth filters.

In this post, we take a look at our vast range of paint spray booth filters and how they can be of benefit to your business.

High quality and high performance

Our spray booth filters are all made to meet EN779:2012 criteria to ensure they are suitable for application and provide the best performance for effective filtration. After all, a high-quality filter is just as important as having regular schedules for changing your spray booth filters. Rest assured, at AGM Services our range of spray booth filters ensures maximum running efficiency.

What is the EN779:2012 criteria?

Spray booth filters and supplies need to meet the European Standard for all air filters, which is the EN779:2012 criteria that came into effect in 2021. Simply put, this standard characterises the filtering performance of building ventilation filters.

A wide range of spray booth filters to choose from

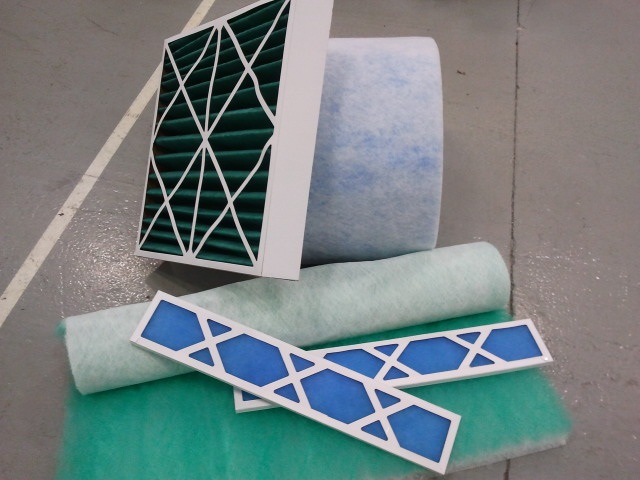

We offer a varied range of filters to choose from, including spray booth ceiling filters (roof filters), pre-filters in cut pads and cartridges, sock filters for spray booth blower systems and various ranges of spray booth extract/floor filters. These range in grades from G (coarse), M (medium) to F (fine).

We can supply filters for any make or model of spray booth oven on the market, cut to size or supplied in bulk rolls. We also offer a monthly filter call-off facility so that you’re not overstocked with bulky rolls of filter on-site.

Thermally-bonded 100% polyester fibres

Our input filters are composed of thermally bonded 100% polyester fibres impregnated in-depth with a tackifier to stop the loss of dust caused by air vibration, increasing the dust holding capacity. Designed to remove all particles above 10 microns, the clean air side is reinforced with a polyester scrim to ensure any loose fibres are not dropped into the airstream and into any paintwork.

Our engineers are here to help

At AGM Services, we have a national network of directly employed engineers who are able to visit your site free of charge and discuss your spray booth filter supply requirements.

As well as changing your filters at the time of service, we can also provide a quote to supply and change your extract filters between services (instead of having to burden your own staff with the responsibility).

If you require more information about our spray booth filters or any other of the services, we encourage you to get in touch with our helpful team by calling 01706 363585 today. If you believe your spray booth needs a service and maintenance check, book one with us today.

Some more resources you might find useful:

How (and why) you need to dispose of your spray booth filters responsibly

Is your spray booth filter ready for life after lockdown?